1. Introduction

RT6204 is a flexible buck converter for wide input

and output voltage range applications. It can be used with input voltages

from 5.2V up to 60V and the output can be adjusted from 0.8V up to 50V,

delivering up to 0.5A output currents. Chapter 2 provides an overview of

the application component selection and design considerations. Chapters

3, 4, 5 and 6 each describe a design with specific VIN/VOUT

condition from low 1.2V MCU supply to industrial supply providing 24V output.

2. RT6204 general design guidelines

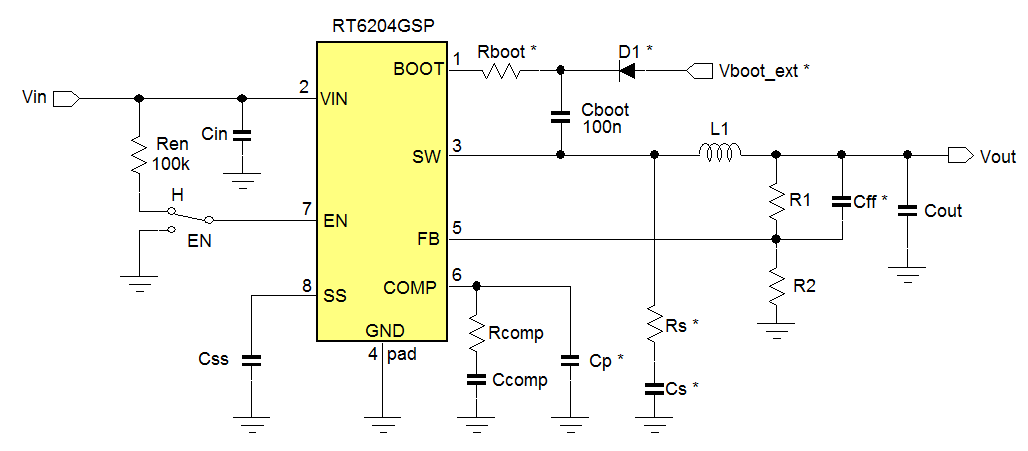

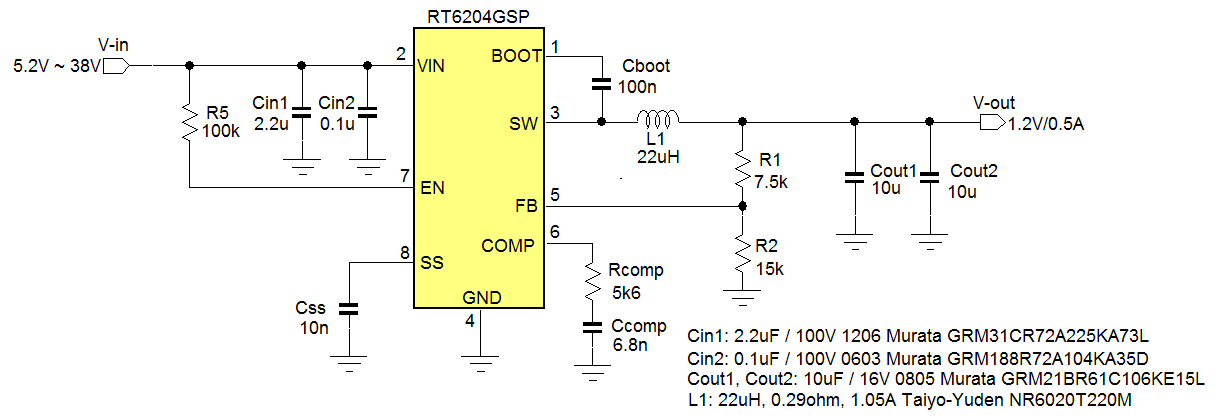

The RT6204 application schematic is shown in figure

1. RT6204 is a current mode converter with external compensation and external

soft-start. The converter has both integrated high-side MOSFET switch and

synchronous rectifier switch. The output can be set via a simple resistor

divider. Current mode control with external compensation makes it possible

to tune the converter control loop for a wide range of output capacitors,

from low ESR ceramic types to aluminum electrolytic capacitors. This gives

the designer the freedom to choose the most suitable and cost effective

components for any output voltage application.

Figure 1

The following guidelines can be used to calculate the

various application components:

· Input

and output voltage considerations:

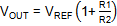

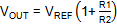

The RT6204 output voltage can be adjusted from 0.8V

to 50V by means of R1 and R2:

The impedance of the feedback network is not critical,

but it is recommended to avoid too high resistor values to reduce sensitivity

to noise. It is recommended to set R2 between 10kΩ ~ 30kΩ.

RT6204 has a low minimum on time of 90nsec, achieving

minimum duty-cycle in CCM mode of 90nsec ‧ 350kHz = 3.15%. It should be noted

that running the converter close to its minimum on time will influence output

ripple and over-current protection behavior. This is explained in chapter

3.

When operating RT6204 in high duty-cycles exceeding

65%, the external bootstrap supply via D1 should be added. The external

bootstrap supply is recommended to be around 3.3~3.8V. (Below 3.5V D1 should

preferably be a Schottky diode)

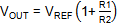

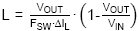

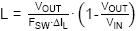

· For Inductor value of L1 there are two main criteria that need to be considered: Inductor current ripple and slope compensation. For applications with duty-cycle

lower than 50%, the inductor can be calculated to provide a ripple current

of 30% of the IC 0.5A rated current (ΔIL = 150mA):

· In applications

where the duty-cycle can exceed 50%, the inductor current falling slope

dI/dt also needs to fit the converter internal slope compensation: L1 value

needs to fulfill the following criteria:

µH

µH

· For output

capacitor selection, there are several considerations:

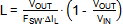

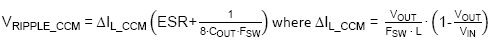

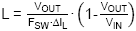

a. Output ripple in CCM mode

Output ripple in CCM mode can be calculated from

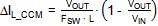

The CCM mode inductor ripple can be calculated from:

When using ceramic output capacitors in these low

voltage supplies, output ripple voltage in CCM mode will be small.

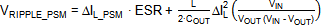

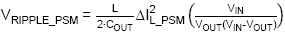

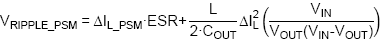

b. Output ripple in PSM mode

Output ripple in PSM mode will depend on the peak

current in PSM mode and the load current. The worst case condition will

happen at zero load:

RT6204 will regulate the inductor peak current in

PSM mode around 150mA but there is around 80nsec propagation delay, so at

high VIN and low VOUT the peak current will increase.

PSM output voltage ripple will always be higher than CCM ripple.

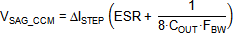

c. Voltage sag during load transients

The voltage sag during a load transient in CCM mode

depends on the load step, control loop speed and output capacitor. An approximate

formula for voltage sag during a fast load step is shown below:

where ΔISTEP is the load step amplitude

and FBW is the converter control bandwidth. Note that load step

transitions between PSM and CCM mode operation will show higher voltage

sag. Converter bandwidth is normally set around 1/10 of the switching frequency,

except when using electrolytic capacitors: The ESR variation over temperature

will require lower bandwidth setting to guarantee stable operation over

the full temperature range. The converter bandwidth can be set via compensation

resistor RCOMP.

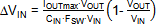

· Input capacitor considerations

The input capacitor provides the high frequency

switching current peaks of the converter. The input capacitor should be

chosen to provide adequate filtering of the converter input, to minimize

the VIN high frequency ripple. Low ESR ceramic capacitors should

be placed close to the converter VIN and GND pins. At high input voltages,

ceramic capacitors will have severely reduced capacitance, which should

be considered when calculating the input ripple voltage. The peak-peak input

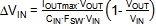

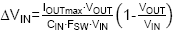

ripple voltage can be approximated by:

where CIN is the capacitance at the DC input voltage.

where CIN is the capacitance at the DC input voltage.

You will normally need at least 1µF capacitance

and 100V rating, which will require 0805 or 1206 size MLCCs.

Another consideration for the input capacitor is

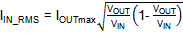

its RMS current rating:

The maximum RMS current will happen when VOUT is 50% of VIN.

The maximum RMS current will happen when VOUT is 50% of VIN.

For the RT6204 maximum load current of 0.5A, the

maximum RSM current in the input capacitor will be 0.25A. This value is

normally not critical for ceramic capacitors with 0805 or 1206 size.

If the converter requires hot-plugging into live

input supplies, it is recommended to add a small electrolytic capacitor

in parallel with the ceramic input capacitor.

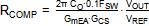

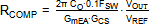

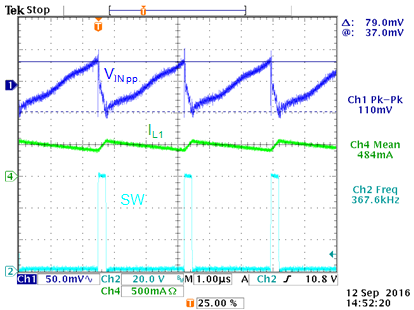

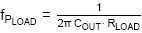

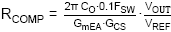

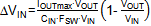

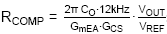

· Calculation of compensation components.

The RT6204 compensation can use standard current

mode type II compensation. The below simple formulas can be used:

The compensator gain is set by RCOMP,

and the value is calculated to provide a suitable converter crossover frequency

(FC around 0.1 ‧ FSW) with sufficient phase

margin.

Note that electrolytic output capacitors will require

lower bandwidth, see chapter 5.

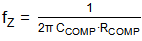

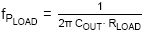

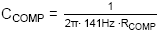

The value of CCOMP is selected to set

the compensation zero

a bit below the converter load pole

a bit below the converter load pole

where RLOAD = VOUT/0.5A.

where RLOAD = VOUT/0.5A.

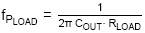

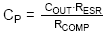

The value for CP is chosen to set the

high frequency pole at the output capacitor ESR zero:

When ceramic output capacitors are used, the ESR

zero will lie at very high frequencies, above the converter switching frequency.

For low VOUT applications with ceramic output capacitors, CP

can be omitted.

The feed-forward capacitor Cff is normally not needed

for improving control loop response. But some small Cff capacitor can sometimes

improve the PSM operation; by injecting some extra ripple on the FB pin

double pulsing can be reduced. This can be tested case by case.

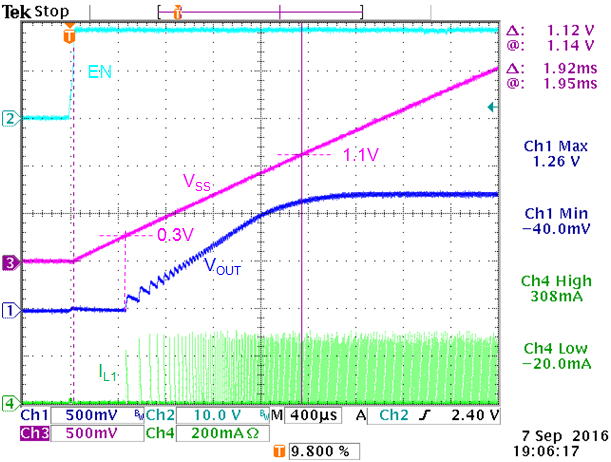

· The soft-start

capacitor sets the time tSS from EN high to VOUT reaching

its final value which is defined by

.

CSS is the value of the soft-start capacitor and ISS

is the soft-start current (typically 6µA). VOUT starts

rising when the VSS ramp passes 0.3V, and ends when VSS

ramp passes 1.1V.

.

CSS is the value of the soft-start capacitor and ISS

is the soft-start current (typically 6µA). VOUT starts

rising when the VSS ramp passes 0.3V, and ends when VSS

ramp passes 1.1V.

The VOUT rise time can therefore be calculated

by:

.

.

Supplies with high output voltage and/or large value

output capacitors should use sufficient soft-start time to avoid high inrush

currents.

· The converter

can be enabled by pulling high the EN pin. The EN logic high level is typically

1.25V. There is a 1µA pull down current on EN. For automatic start-up

when VIN is applied, the EN pin can be connected with a 100k

pull-up resistor to VIN. The EN pin is 60V tolerant.

3. First Example application: 1.2V output

In this first example we will design a converter

with a fixed 1.2V output with a wide input voltage range.

· Maximum

input voltage: Based on minimum on time, the maximum input voltage for 1.2V

output will be 1.2/0.0315 = 38V. In this 1.2V example we will examine how

the minimum on time will influence output ripple and over-current protection

performance.

· Feedback

network: use

to select R1 and R2: In this case we choose R1 = 7.5k and R2 = 15k which

will give exactly 1.2V output.

to select R1 and R2: In this case we choose R1 = 7.5k and R2 = 15k which

will give exactly 1.2V output.

· Inductor

value: For this 1.2 application, the duty-cycle will never reach 50%, so

slope compensation is not critical in this case. Therefore, the inductor

calculation can be purely based on ripple current.

Using VIN = 38V, and current ripple of

0.3 ‧ 0.5A=0.15A: using

we find L = 22.1µH.

we find L = 22.1µH.

At max 0.5A load, the inductor peak current will

be (1+0.15) ‧ 0.5A = 0.575A. Normally the saturation current is chosen at

least 10% higher than the maximum peak current, so Isat should be > 0.63A.

For this example a Taiyo-Yuden NR6020T 22µH with Isat of 1A was chosen.

· For output

capacitor selection, we use the PSM ripple as selection criteria:

First the PSM peak current is estimated: With VIN

= 38V, VOUT = 1.2V, L = 22µH, the inductor current rising

slope is

(38-1.2)/22µH = 1.67A/µsec. 80nsec propagation

delay will result in 0.133A current increase. The PSM peak current will

therefore be around 280mA. For 1.2V output supply, we will use low ESR ceramic

capacitors. The capacitor ESR can therefore be neglected, and the PSM ripple

formula can be simplified:

.

.

A worst case PSM ripple of 50mVpp requires 15.7µF

capacitance. For this example two 10µF/16V 0805 X5R size MLCC output

capacitors were selected: Murata GRM21BR61C106KE. The MLCC capacitance drop

due to 1.2V dc bias voltage is very low and can be neglected. But MLCC capacitance

is normally rated at an AC voltage of around 0.5Vrms. The capacitance will

drop at lower AC RMS voltage. For this low voltage ripple application, a 27%

capacitance drop must be considered. For more details on MLCC capacitor

behavior, please see

http://ds.murata.com/software/simsurfing/en-us/

The total effective output capacitance becomes ~15µF

output capacitance, which is used for further calculations.

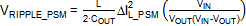

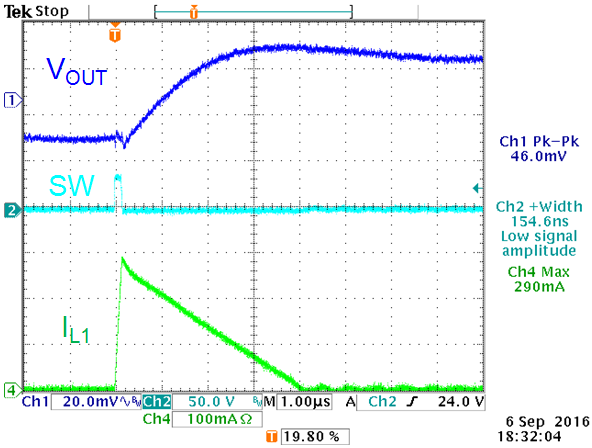

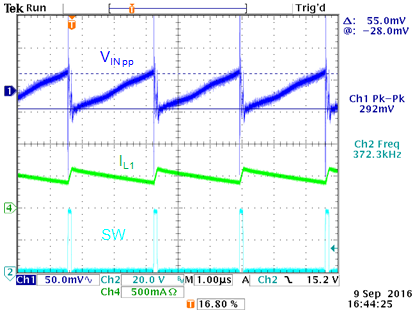

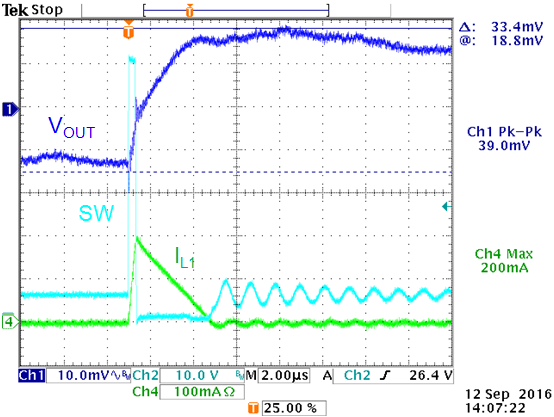

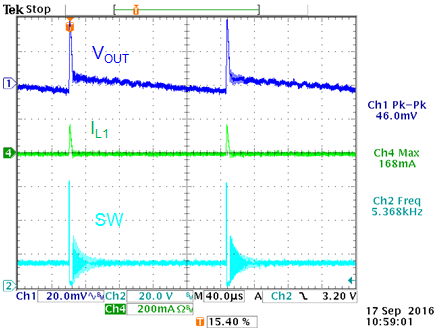

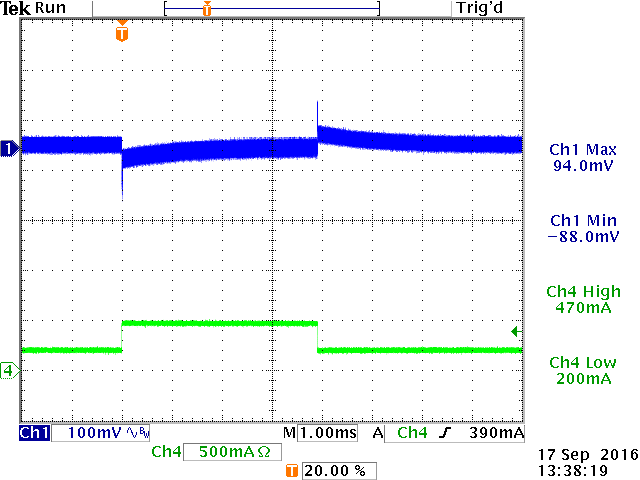

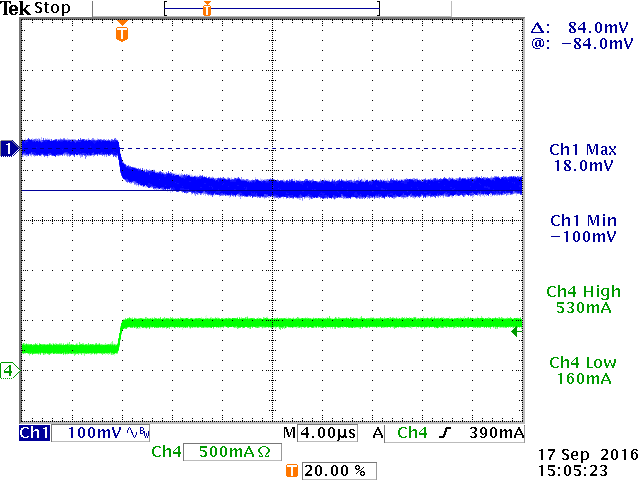

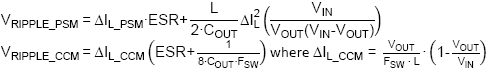

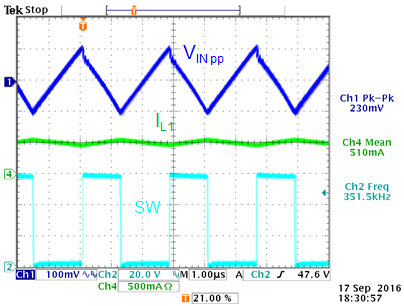

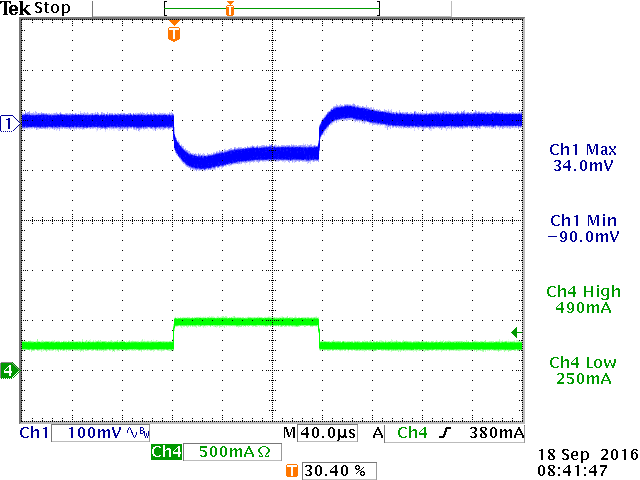

Measurements of the output ripple in PSM mode are

shown in the figure 2 below: L1 = 22µH, COUT_eff = 15µF

|

VIN = 38V, VOUT =

1.2V, 1mA load

|

PSM ripple with 15µF capacitance is

46mVpp.

|

|

|

|

Figure 2

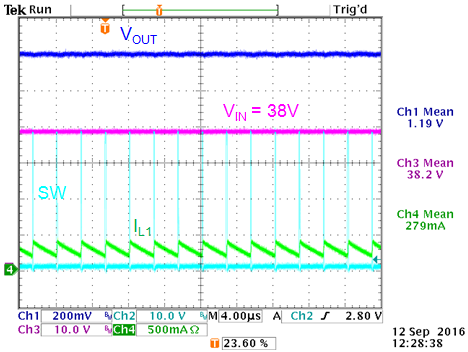

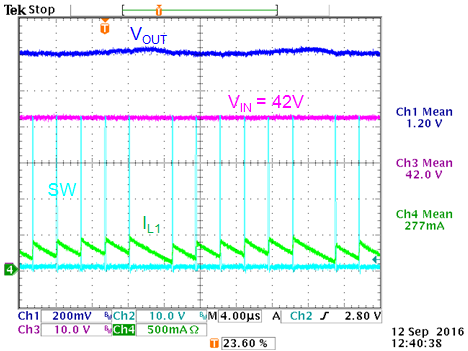

The effect of minimum ON time limit at high VIN

is shown in the figure 3 below: (VOUT = 1.2V, 0.28A load)

|

VIN = 38V: Just full PWM, no

pulse skipping

|

VIN = 42V: min ON time limit reached,

pulse skipping

|

|

|

|

Figure 3

When the minimum ON time is reached in high VIN

low VOUT applications, the converter will start skipping pulses

to maintain regulated output. This pulse skipping will result in higher

output voltage ripple.

· For the

input capacitor selection, the maximum allowed input ripple needs to be

considered. The input capacitor also needs to have sufficient voltage rating.

For 40V input range, a capacitor having least 60V voltage rating needs to

be used. This normally means a ceramic capacitor with 100V rating.

According

with 0.5A load current, 38V input and 1.2V output, 1µF of input capacitance

means that the input ripple will be around 44mV ripple. It should be noted

that this ripple does not include high frequency ringing due to capacitor

ESL and layout ESL.

with 0.5A load current, 38V input and 1.2V output, 1µF of input capacitance

means that the input ripple will be around 44mV ripple. It should be noted

that this ripple does not include high frequency ringing due to capacitor

ESL and layout ESL.

In this example we used a small 100nF/100V 0603

X7R capacitor (Murata GRM188R72A104KA35) in parallel with a 2.2µF/100V

1206 X7R capacitor (Murata GRM31CR72A225KA73) which has an effective capacitance

of 1.1µF at 38Vdc.

|

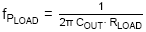

|

Figure 4 shows the input ripple voltage

measurement at 38V input and 0.5A load current.

The ripple voltage shows a saw-tooth with

55mVpp amplitude, but there is also considerable high frequency

noise present, due to parasitic ESL. To avoid this high frequency

noise entering the input power lines, it is recommended adding additional

filtering by means of a high frequency bead and extra capacitance.

The worst case RMS current in the input

capacitor for this application happens at the lowest input voltage

(5.2V), and will be around 0.2A. This will not be a problem for

the selected input capacitors.

|

|

Figure 4

|

|

· Calculation

of compensation components.

For the compensation component calculations we will

use the formulas as given in chapter 2. For the output capacitance we use

COUT_eff =15µF.

: With GmEA = 970µA/V, GCS = 0.9A/V and COUT_eff

= 15µF: RCOMP becomes 5.7kΩ

: With GmEA = 970µA/V, GCS = 0.9A/V and COUT_eff

= 15µF: RCOMP becomes 5.7kΩ

We will choose 5.6kΩ

The converter load pole

lies at 4.4kHz.

lies at 4.4kHz.

= 6.4nF

= 6.4nF

We will choose 6.8nF.

The ceramic output capacitors will have a combined

ESR of 2.5mΩ. The ESR zero lies at 4.2MHz. CP can be omitted.

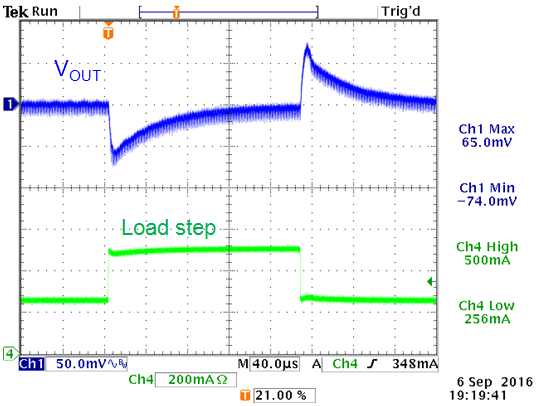

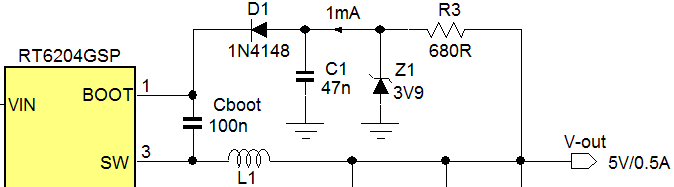

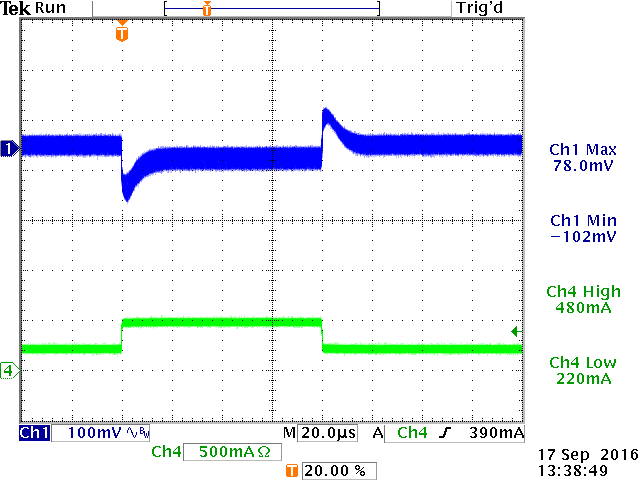

Converter stability was checked by means of fast

load step, see figure 5.

|

|

Fast load step at 24V input shows stable

performance without ringing.

Converter sag at 250mA load step shows 74mV

|

|

Figure 5

|

|

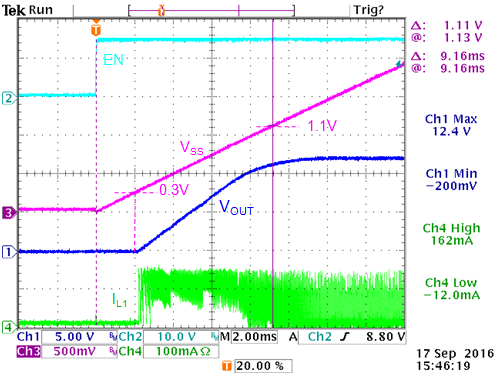

· The soft-start

capacitor sets the time tSS from EN high to VOUT reaching

its final value which is defined by

.

CSS is the value of the soft-start capacitor and ISS

is the soft-start current (typically 6µA).

.

CSS is the value of the soft-start capacitor and ISS

is the soft-start current (typically 6µA).

For the 1.2V application with relatively small output

capacitors, inrush current is not critical. CSS = 10nF gives

a total start-up time of 1.83msec and VOUT rise time of 1.3msec.

|

|

Figure 6 shows the soft-start behavior:

When EN goes high, the soft-start ramp starts rising. The converter

starts switching when the soft-start ramp passes 0.3V and VOUT

rises. Switching frequency gradually increases as VOUT

increases.

When the soft-start ramp reaches 1.1V, the

converter output reaches its final value.

|

|

Figure 6

|

|

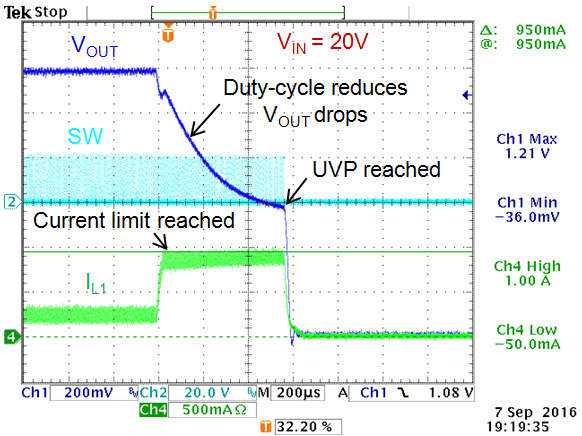

· Over-current

protection behavior:

RT6204 has a cycle by cycle peak current limiting

circuit that uses the high side MOSFET current sense. When the converter

output loading is increased, at some point the peak current limit will be

reached: the protection circuit will then reduce the high side MOSFET on

time to avoid further current rise.

|

|

Figure 7 shows the current limit measurement

at VIN = 20V: When the inductor current reaches 950mA,

the duty-cycle is reduced and VOUT starts to drop. The

over current protection level of this 20V – 1.2V application is

slightly higher than the datasheet OCP level due to the current

sense propagation delay: (20-1.2)/22µH = 0.85A/µsec.

80nsec propagation delay will result in 0.068A current increase.

When VOUT drops below the output

under voltage protection (UVP level is 50% of VOUT),

the converter shuts down, and an automatic soft-start cycle is initiated.

|

|

Figure 7

|

|

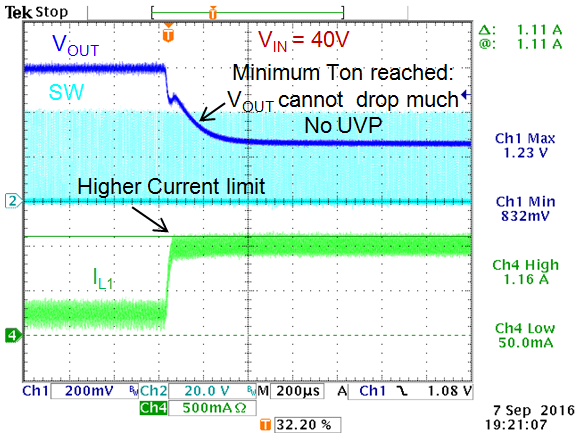

When the RT6204 converter is operating in high input

voltage and low output voltage conditions and is subjected to overload situations,

it is important to make sure that the converter’s minimum on-time does not

prevent the current limit from operating properly. In minimum on time operation

mode and overload condition, the converter will operate at the minimum duty

and the output voltage will remain at whatever voltage that duty naturally

produces. In this overloaded state the inductor current is no longer controlled

and depends mainly on the load current, which eventually becomes high enough

for the MOSFET and inductor component voltage drops to increase enough to

allow VOUT to reach 50% and trigger UVP protection.

|

|

Figure 8 shows the current limit measurement

at VIN = 40V: Due to propagation delay, the OC level

now lies around 1.1A. The converter tries to reduce duty-cycle,

but it is operating close to its minimum TON time. It can be seen

that VOUT cannot drop much more and gets “stuck” around

830mV. The UVP level cannot be reached and the converter keeps operating

in this maximum overload condition.

When the converter load is further increased,

the inductor current can actually increase beyond the over current

limit. Any VOUT drop will now be caused by Rdson and

inductor DCR drop, which may still trigger UVP protection.

|

|

Figure 8

|

|

When the RT6204 converter is operating in high input

voltage and low output voltage conditions in combination with overload situations,

it is important to check the minimum on time limitations.

The complete 1.2V application is shown in figure

9.

Figure 9

4. Second Example application: 5V output

The second example explains the converter with a

fixed 5V output with a wide input voltage range.

· The maximum

input voltage for this case is limited by the RT6204 60V maximum voltage

rating: 5/60 = 8.3%, which is much larger than the RT6204 minimum duty-cycle

of 3.15%. If the input supply can be lower than 7.5V, the duty-cycle will

be higher than 65%, and the external bootstrap diode needs to be implemented.

· Feedback

network: use

to select R1 and R2: In this case we choose R1 = 43k and R2 = 8.2k which

will give 4.995V output.

to select R1 and R2: In this case we choose R1 = 43k and R2 = 8.2k which

will give 4.995V output.

· Inductor

value: For this 5V application, the duty-cycle can exceed 50% when VIN

is lower than 10V: for wide VIN applications, the effect of slope

compensation on the minimum required inductance needs to be considered.

The slope compensation criteria

requires an inductor greater than 83µH.

requires an inductor greater than 83µH.

Inductor calculation based on 30% current ripple

at 60V input using

will give L = 87.3µH. In this example we will use 100µH. The

selected inductor is a 100µH Wuerth Electronic 744066101 shielded

inductor with a 1.2A saturation current and 0.255Ω resistance.

will give L = 87.3µH. In this example we will use 100µH. The

selected inductor is a 100µH Wuerth Electronic 744066101 shielded

inductor with a 1.2A saturation current and 0.255Ω resistance.

· For output

capacitor selection, we use the PSM ripple as selection criteria:

First the PSM peak current is estimated: With VIN

= 60V, VOUT = 5V, L = 100µH, the inductor current rising

slope is

(60-5)/100µH = 0.55A/µsec. 80nsec propagation delay

will result in 0.044A current increase. The PSM max peak current will therefore

be around 194mA. Note that at lower VIN, peak current increase

due to propagation delay is very small, and the nominal 150mA PSM peak current

can be used. For this 5V output supply, we will use low ESR ceramic capacitors.

The capacitor ESR can therefore be neglected, and the PSM ripple formula

will be:

At 60V input, a PSM ripple of 50mVpp requires around

9µF capacitance. For this example we used two 10µF/25V X5R 1206

size MLCC output capacitors, each having an effective capacitance of 6µF

at 5Vdc bias and low AC ripple voltage. The effective capacitance becomes

12µF output capacitance, which is used for further calculations.

Calculated PSM ripple at 60V input with 12µF output capacitance will

be 37mVpp.

|

|

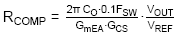

Figure 10 shows the zero load PSM ripple

for the 5V application with 60V input and 12µF effective output

capacitance. PSM peak current and 39mVpp output ripple matches the

calculated values quite well.

|

|

Figure 10

|

|

· For the

input capacitor selection, the maximum allowed input ripple needs to be

considered. The input capacitor also needs to have sufficient voltage rating.

For 60V input range, a capacitor having least 90V voltage rating needs to

be used. This normally means a ceramic capacitor with 100V rating.

According

with 0.5A load current, 60V input and 5V output, 1µF of input capacitance

gives input ripple will be around 110mV ripple. It should be noted that

this ripple does not include high frequency ringing due to capacitor ESL

and layout ESL.

with 0.5A load current, 60V input and 5V output, 1µF of input capacitance

gives input ripple will be around 110mV ripple. It should be noted that

this ripple does not include high frequency ringing due to capacitor ESL

and layout ESL.

In this example we used a small 100nF/100V 0603

X7R capacitor (Murata GRM188R72A104KA35) in parallel with two pieces 2.2µF/100V

1206 X7R capacitor (Murata GRM31CR72A225KA73) each having an effective capacitance

of 0.7µF at 60Vdc. The total combination of 1.5µF would give

around 78mVpp calculated input ripple at 60Vdc input and 0.5A load.

The worst case RMS current in the input capacitor

in this 5V application will happen when VIN is 10V and the load

is 0.5A. The maximum RMS current will be 0.25A; this will not be a problem

for the selected input capacitors.

|

|

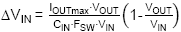

Figure 11 shows the actual input ripple

measurement, which shows 79mV saw-tooth input ripple. Additional

high frequency noise is due to parasitic inductance.

|

|

Figure 11

|

|

· Calculation

of compensation components.

For the compensation component calculations we will

use the formulas as given in chapter 2. For the output capacitance we use

COUT_eff = 12µF.

: With GmEA = 970µA/V, GCS = 0.9A/V and COUT_eff

= 12µF: RCOMP becomes 19kΩ. We will choose 18kΩ.

: With GmEA = 970µA/V, GCS = 0.9A/V and COUT_eff

= 12µF: RCOMP becomes 19kΩ. We will choose 18kΩ.

The converter load pole

lies at 1.3kHz.

lies at 1.3kHz.

= 6.8nF.

= 6.8nF.

The ceramic output capacitors will have a combined

ESR of 2.5mΩ. The ESR zero lies at 5.3MHz. CP calculation

based on this ESR zero will be 1.6pF. But for higher output voltage application

with larger duty-cycle variation, a larger value of CP is recommended.

The datasheet recommended value of 47pF sets the compensator pole at 188kHz,

which makes the converter operate more stable at higher duty-cycles at the

expense of slightly lower overall phase margin.

|

|

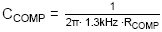

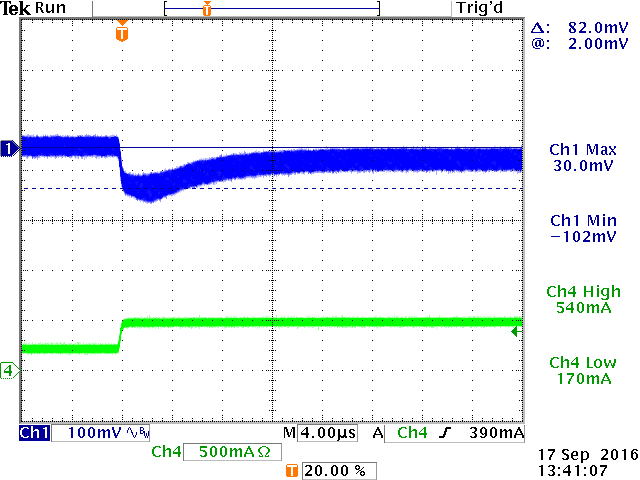

Figure 12 shows the output response with

a fast load step from 200mA to 420mA. (Converter operating in CCM

mode with an input voltage of 50V)

The response is stable without ringing.

Converter voltage sag at 220mA load step shows 90mV.

|

|

Figure 12

|

|

· For this

5V application with relatively small output capacitance, inrush current

is not critical. The same 10nF soft-start capacitance as used for 1.2V application

can be used, which gives total start-up time of 1.83msec based on:

.

VOUT rise time from zero to 5V will be 1.3msec.

.

VOUT rise time from zero to 5V will be 1.3msec.

· External

Bootstrap capacitor charging circuit.

If the converter input can be lower than 7.5V, the

external bootstrap supply is needed. The optimal value for this bootstrap

supply is around 3.3V: Higher values like 5V can lead to too strong high-side

MOSFET drive which can lead to noise and unstable switching at certain conditions.

The 3.3V bootstrap supply can be derived from the 5V output by using a zener

voltage clamp. The average current that the external bootstrap circuit needs

to supply is low, around 1mA max. The peak current in D1 is around 40mA

max, and a small buffer capacitor can be used to supply this current.

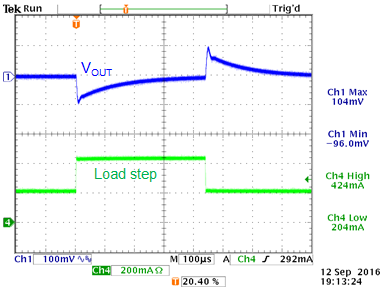

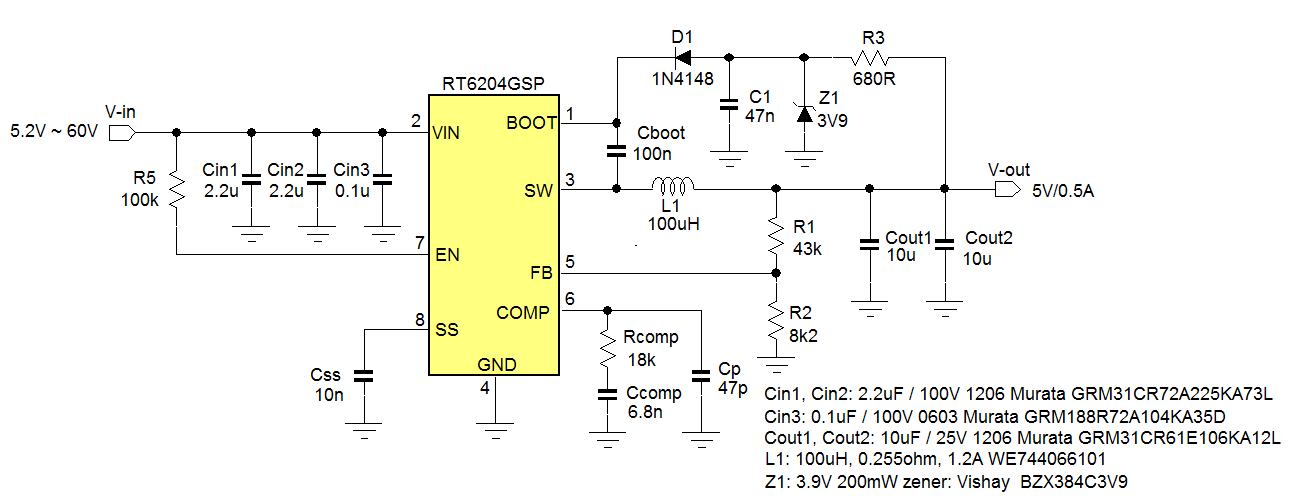

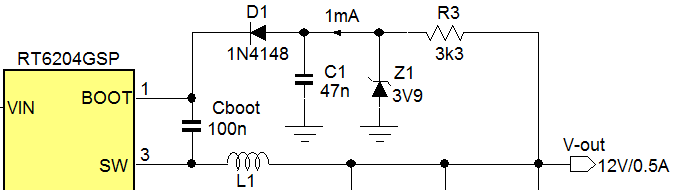

For the external bootstrap supply we will use zener

clamp circuit: See figure 13.

Figure 13

To minimize the power needed for the circuit, the

zener current is kept low, around 1mA. To compensate for the lower zener

knee voltage at low current, a higher voltage zener diode is chosen, Vishay

BZX384C3V9. Using a 680Ω bias resistor, at 5V output and 1mA bootstrap

charging current, the current in the zener will be around 1.5mA with a zener

clamping voltage of 3.5V. The total power dissipation in R3 is 2.5mA2 ‧ 680Ω

= 4.25mW, so a small size SMD resistor can be used. The 47nF capacitor provides

sufficient buffer for the 40mA D1 current pulses.

When the converter goes into max duty-cycle dropout

mode, VOUT will reduce and the external boot supply will drop

to around 3.2V. This is still sufficient to drive the bootstrap supply.

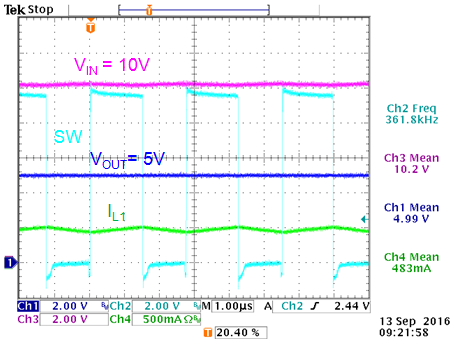

The figure 14 below shows the 5V converter operation

at maximum load when VIN is reduced: The maximum duty-cycle is

determined by the converter minimum off time which is around 200nsec, which

results in 93% max duty-cycle. The input voltage where the converter reaches

the max duty-cycle is heavily dependent on load current: The I ‧ Rdson drop

and inductor I ‧ DCR drop need to be included, which is around 0.45V at 0.5A

load. The VIN where drop-out starts to happen is then 5V/0.93

+ 0.45V = 5.82V.

|

VIN = 10V: 50% duty-cycle

VOUT = 5V

|

VIN = 6V: close to max duty-cycle:

VOUT = 5V

|

VIN = 5V: dropout mode in max

duty-cycle operation. VOUT = 4V

|

|

|

|

|

Figure 14

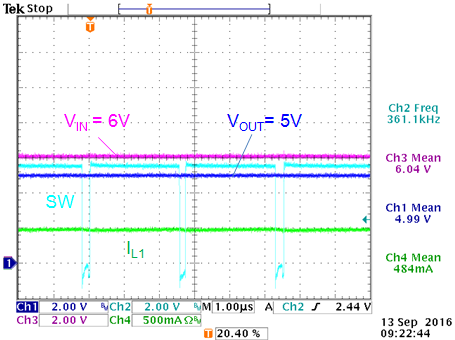

The total 5V application schematic is shown in figure

15.

Figure 15

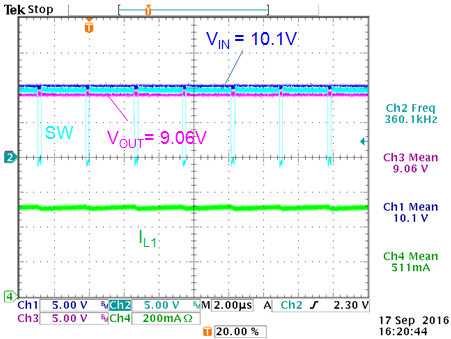

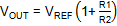

5. Third Example application: 12V output

The third example analyzes the converter with a

fixed 12V output and a wide input voltage range.

· The maximum input voltage for the 12V output case is the same as

for the 5V case: it is limited by the RT6204 60V maximum input voltage rating.

If the input supply can be lower than 18.5V, the duty-cycle will be higher

than 65%, and the external bootstrap charging circuit needs to be implemented.

· Feedback network: use

to select R1 and R2: In this case we choose R1 = 140k and R2 = 10k as shown

in the datasheet.

to select R1 and R2: In this case we choose R1 = 140k and R2 = 10k as shown

in the datasheet.

· Inductor value: For this 12V application, the duty-cycle can exceed

50% when VIN is lower than 24V, so for wide VIN applications,

the effect of slope compensation on the minimum required inductance needs

to be considered. The slope compensation criteria

requires an inductor greater than 200µH.

requires an inductor greater than 200µH.

Inductor calculation based on 30% current ripple

at 60V input using

gives L = 183µH. In this example we will use 220µH. The selected

inductor is Bourns SRU1048A-221Y shielded inductor with a 0.7A saturation current

and 0.455Ω resistance.

gives L = 183µH. In this example we will use 220µH. The selected

inductor is Bourns SRU1048A-221Y shielded inductor with a 0.7A saturation current

and 0.455Ω resistance.

· Output

capacitor choice: For this 12V application you could either choose ceramic

or electrolytic output capacitors. MLCC ceramic capacitors have considerable

capacitance drop due to 12V dc bias, and you’ll need larger case size MLCC

or several pieces in parallel to reach an effective capacitance above 10µF.

For example, the 10µF/25V X5R 1206 size MLCC GRM31CR61E106KA12L will

have around 2.9µF at 12Vdc and low ac ripple. Two pieces in parallel

will give 5.8µF.

A small SMD aluminum electrolytic capacitor of 47µF,

35V, 6.3x5.8mm size (like the Panasonic VFK Series) has an ESR of 0.36Ω

and a rated RMS current of 240mA. You can calculate the output ripple for

both types in PSM mode and CCM mode. The PSM peak current can be calculated

in a similar way as the 5V example, and will be around 165mA for a 60V –

12V application with a 220µH inductor. The CCM ripple current will

be around 124mApp.

PSM ripple at 60V input with 5.8µF MLCC output

capacitance will be around 55mVpp.

CCM ripple at 60V input with 5.8µF MLCC output

capacitance will be around 8mVpp.

PSM ripple at 60V input with 47µF electrolytic

capacitor with 0.36Ω ESR will be around 59mVpp.

CCM ripple at 60V input with 47µF electrolytic

capacitor with 0.36Ω ESR will be around 46mVpp.

As can be seen, the PSM output ripple for both types

of capacitor are quite close, but MLCC capacitors will have lower ripple

in CCM mode. But if you do the calculations at lower input voltage, you’ll

find that the electrolytic capacitor will have lower PSM ripple than the

MLCC capacitors.

For this 12V output example, we will use the 47µF/35V

6.3x5.8mm electrolytic capacitor with ESR 0.36Ω.

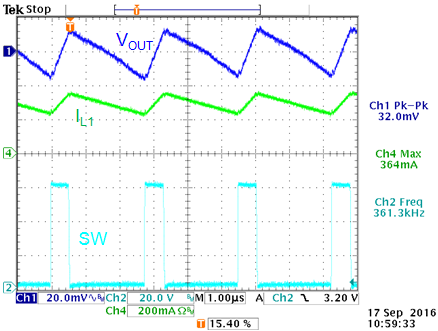

Figure 16 shows the measured output ripple in PSM

mode and CCM mode when using this electrolytic output capacitor.

|

12V output ripple in PSM mode with electrolytic

capacitor: Ripple voltage is 46mVpp

|

12V output ripple in CCM mode with electrolytic

capacitor: Ripple voltage is 32mVpp

|

|

|

|

Figure 16

It should be noted that electrolytic capacitor ESR

is heavily dependent on temperature: ESR becomes higher at lower temperatures.

This effect should be included when the power supply has to operate at lower

temperatures.

It is recommended to place a small 100nF/50V ceramic

capacitor in parallel with the electrolytic output capacitor: The low ESR

ceramic capacitor will filter the high frequency spikes from the switching

transitions. But this capacitor will not have any effect on the ripple amplitude

or converter stability.

· For the

input capacitor selection we’ll use the same values as were used in the

5V output example:

A small 100nF/100V 0603 X7R capacitor (Murata GRM188R72A104KA35)

in parallel with two pieces 2.2µF/100V 1206 X7R capacitor (Murata

GRM31CR72A225KA73) giving a total combination of 1.5µF.

From

with a maximum 0.5A load current, 60V input and 12V output, 1.5µF

of input capacitance will give an input ripple of around 152mVpp.

with a maximum 0.5A load current, 60V input and 12V output, 1.5µF

of input capacitance will give an input ripple of around 152mVpp.

The worst case RMS current in the input capacitor

in this 12V application will happen when VIN is 24V and the load

is 0.5A. The maximum RMS current will be 0.25A; this will not be a problem

for the selected input capacitors.

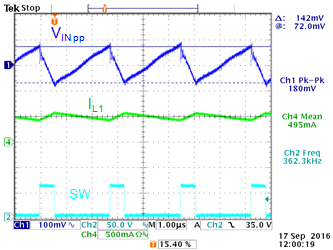

|

|

Figure 17 shows the actual input ripple

measurement, which shows 142mV saw-tooth input ripple. Additional

high frequency noise is due to parasitic inductance.

|

|

Figure 17

|

|

· Calculation

of compensation components.

For the compensation component calculations we will

use the formulas as given in chapter 2. For the output capacitance we use

COUT = 47µF and Output capacitor ESR = 0.36Ω. We

will first use the standard bandwidth setting of 0.1 ‧ FSW:

: With GmEA = 970µA/V, GCS = 0.9A/V and COUT

= 47µF: RCOMP becomes 178kΩ. We will choose

180kΩ.

: With GmEA = 970µA/V, GCS = 0.9A/V and COUT

= 47µF: RCOMP becomes 178kΩ. We will choose

180kΩ.

The converter load pole

lies at 141Hz.

lies at 141Hz.

= 6.3nF. We choose 6.8nF.

= 6.3nF. We choose 6.8nF.

The output capacitor ESR of 0.36Ω will result

in an ESR zero of at 9.4kHz. From

we can find that CP needs to be 95pF. We’ll choose 100pF.

we can find that CP needs to be 95pF. We’ll choose 100pF.

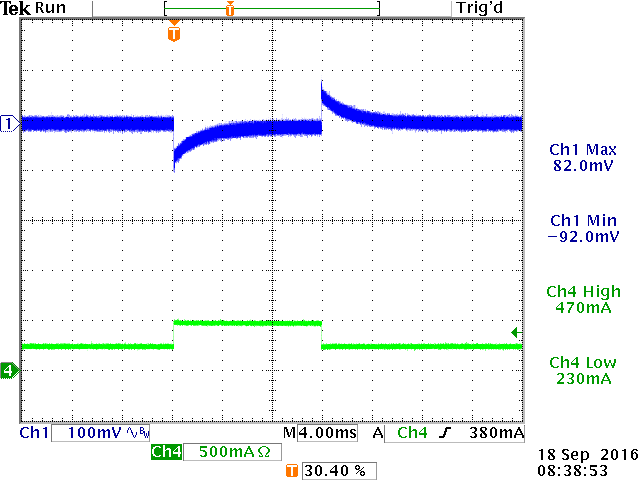

Figure 18 show the step load response at room temperature,

with a fast load step from 250mA to 500mA.

|

4msec step at 25oC: VOUT

recovery time around 3msec due to RCOMP ‧ CCOMP

time constant.

|

80µsec step shows the initial VOUT

drop due output cap ESR.

|

Zoom of ESR drop confirms the voltage drop

to be ΔILOAD ‧ ESR

(250mA ‧ 0.36Ω = 90mV)

|

|

|

|

|

Figure 18

As mentioned earlier, electrolytic capacitor ESR

is heavily dependent on temperature: ESR becomes much higher at lower temperatures.

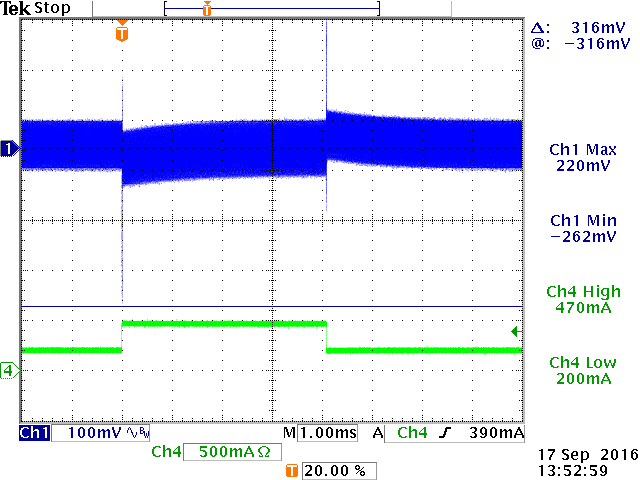

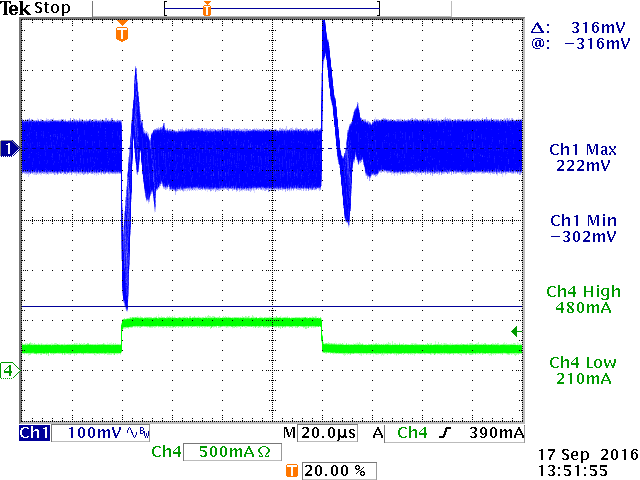

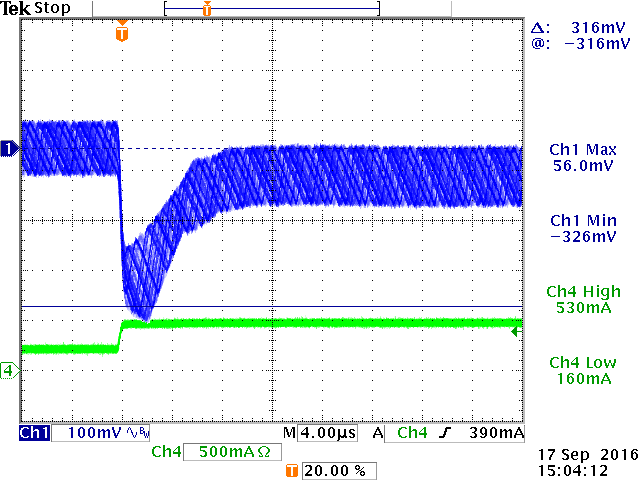

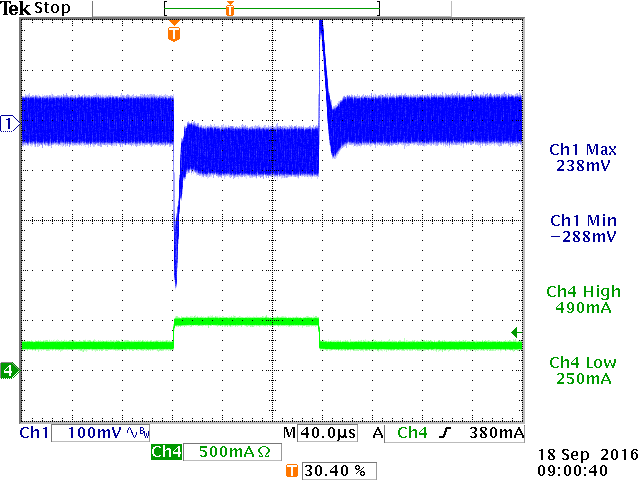

Below figure 19 show the step response at -20oC:

|

4msec step at -20oC; Increased

ripple.

|

80µsec step at -20oC shows

instability.

|

Zoom shows a voltage drop to be ΔILOAD ‧ ESR

to be 316mV:

ESR is now 316mV/250mA = 1.26Ω

|

|

|

|

|

Figure 19

Clearly the converter is not stable at lower temperatures.

What happened is that the increased output capacitor ESR at low temperature

sets the modulator ESR zero at much lower frequency, around 2.6kHz. This

increases the modulator gain at high frequencies and results in a much higher

control bandwidth. The phase margin will be poor.

To overcome this problem the compensation needs

to be adjusted: You could just increase the value of CP, but

this will reduce phase margin at room temperature ESR. It is better to reduce

the overall converter bandwidth by reducing RCOMP considerably.

This will give the best phase margin in both high ESR (low temperature)

and low ESR (high temperature) condition.

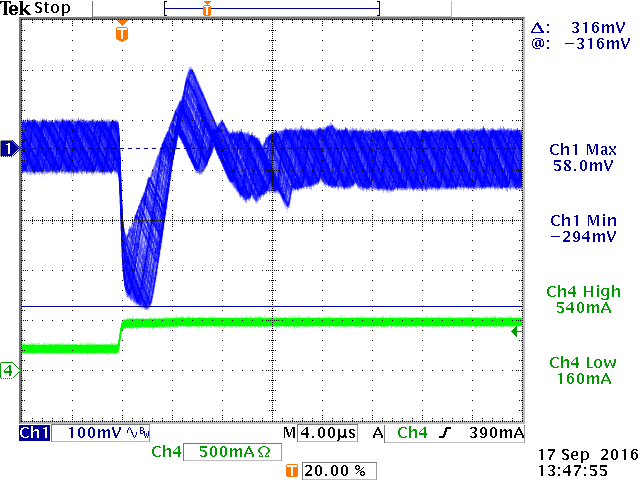

In this case we lower the bandwidth with a factor

3 to around 13kHz: RCOMP becomes 68k. CCOMP now becomes

15nF. Calculate CP for room temperature ESR of 0.36Ω: CP

becomes 250pF, choose 270pF. The figure 20 below show the result: The step

load response now looks good at both low temperature and high temperature

conditions.

|

Load step at +25oC : OK

|

Load step at -30oC : OK

|

Load step at +70oC : OK

|

|

|

|

|

Figure 20

· Soft-start

design: For the 12V application with 47µF output capacitance, too

fast VOUT rise time can result in some inrush current: To keep

the inrush during VOUT rise less than 100mA, the rise time must

be greater than 47µF ‧ 12V/100mA = 5.6msec.

, so CSS needs to be larger than 42nF. We will choose 47nF. This

gives total start-up time of 8.6msec and VOUT rise time from

0 to 12V will be 6.3msec.

, so CSS needs to be larger than 42nF. We will choose 47nF. This

gives total start-up time of 8.6msec and VOUT rise time from

0 to 12V will be 6.3msec.

|

|

Figure 21 shows the soft-start behavior

of the 12V application.

|

|

Figure 21

|

|

| |

|

|

· External

Bootstrap capacitor charging circuit.

If the converter input can be lower than 18.5V,

the external bootstrap supply is needed. The optimal value for this bootstrap

supply is around 3.3V: Higher values like 5V can lead to too strong high-side

MOSFET drive which can lead to noise and unstable switching at certain conditions.

The 3.3V bootstrap supply can derived from the 12V output by using a zener

voltage clamp similar to the 5V application. With an average bootstrap charge

current of 1mA and a zener bias current of 1.5mA, the zener bias resistor

R3 becomes (12V-3.3V)/2.5mA = 3.5k. We will choose 3.3k. The total power dissipation

in R3 is 2.5mA2 ‧ 3.3kΩ = 20mW, so a small size SMD resistor

can be used. The circuit is shown in figure 22.

Figure 22

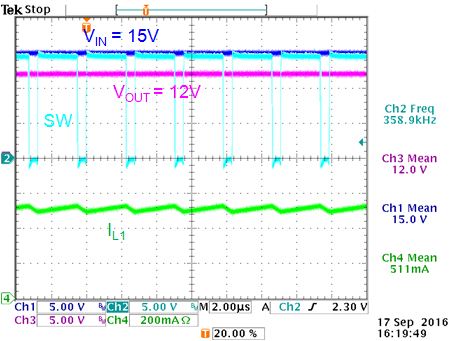

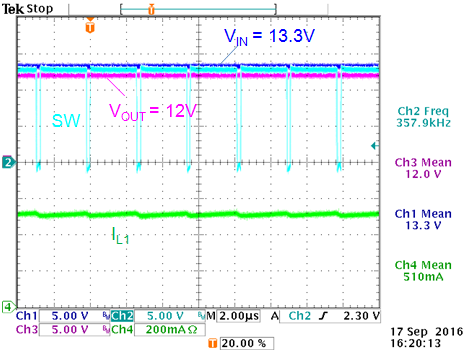

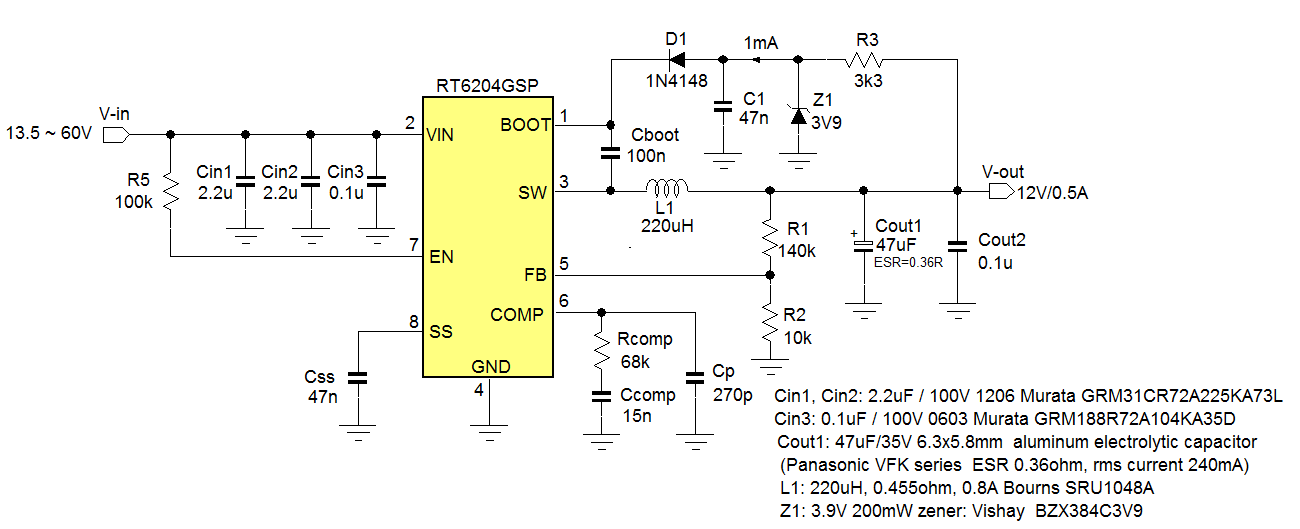

Figure 23 below shows the 12V converter operation

at maximum load when VIN is reduced: The maximum duty-cycle is

determined by the converter minimum off time which is around 200nsec, which

results in 93% max duty-cycle. The input voltage where the converter reaches

the max duty-cycle depends on load current: The I ‧ Rdson drop and inductor

I ‧ DCR drop need to be included, which is around 0.66V at 0.5A load for the

12V application. The VIN where drop-out starts to happen is then

12V/0.93 + 0.66V = 13.56V.

|

VIN = 15V: ~80% duty-cycle

VOUT = 12V

|

VIN = 13.3V: just at max duty-cycle:

VOUT = 12V

|

VIN = 10.1V: dropout mode in

max duty-cycle operation. VOUT = 9.06V

|

|

|

|

|

Figure 23

The total 12V application schematic is shown in

figure 24.

Figure 24

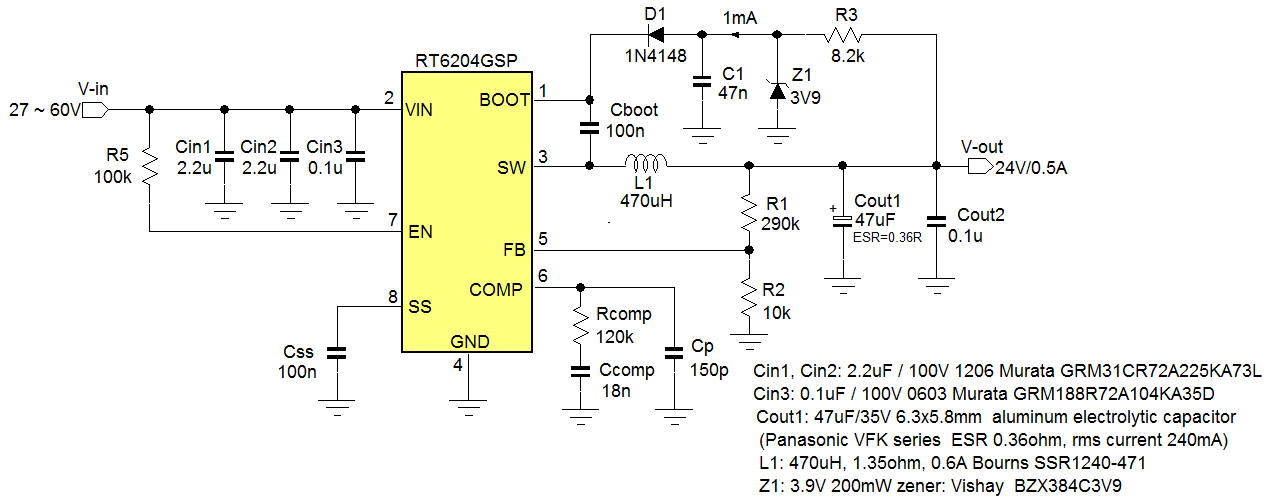

6. Fourth Example application: 24V output

This fourth example examines the converter with

a fixed 24V output and a wide input voltage range.

· The maximum input voltage for the 24V output case is the same as

for the 12V case: it is limited by the RT6204 60V maximum input voltage

rating. If the input supply can be lower than 37V, the duty-cycle will be

higher than 65%, and the external bootstrap charging circuit needs to be

implemented.

· Feedback network: use

to select R1 and R2: In this case we choose R2 = 10k and R1 = 290k.

to select R1 and R2: In this case we choose R2 = 10k and R1 = 290k.

· Inductor value: For this 24V application, the duty-cycle can exceed

50% when VIN is lower than 48V, so for wide VIN applications,

the effect of slope compensation on the minimum required inductance needs

to be considered. The slope compensation criteria

(µH) requires an inductor greater than 400µH.

(µH) requires an inductor greater than 400µH.

Inductor calculation based on 30% current ripple

at 60V input using

gives L = 274µH. So we need to select the inductor based on slope

compensation criteria. In this example we will use 470µH. The selected

inductor is Bourns SSR1240-471 shielded inductor with a 0.6A saturation

current and 1.35Ω resistance.

gives L = 274µH. So we need to select the inductor based on slope

compensation criteria. In this example we will use 470µH. The selected

inductor is Bourns SSR1240-471 shielded inductor with a 0.6A saturation

current and 1.35Ω resistance.

· Output

capacitor choice: For this 24V application, MLCC ceramic capacitors are

not really suitable due to their large capacitance drop at high DC bias

voltage. To achieve sufficient capacitance, you’d need large size 50V MLCC

types, which are quite expensive.

Small SMD aluminum electrolytic capacitors are more

suitable. In the 12V output application we used 47µF, 35V, 6.3x5.8mm

size (Panasonic VFK Series) with an ESR of 0.36Ω and a rated RMS current

of 240mA. We can consider using this capacitor for the 24V application as

well.

You can calculate the output ripple in PSM mode

and CCM mode. The PSM peak current for this 24V case will be the IC regulated

PSM peak value of 150mA, without much propagation delay influence. The CCM

ripple current with 470u inductor will be around 88mApp.

PSM ripple at 60V input with 47µF electrolytic

capacitor with 0.36Ω ESR will be around 62mVpp.

CCM ripple at 60V input with 47µF electrolytic

capacitor with 0.36Ω ESR will be around 32mVpp.

For this 24V output example, we will use the 47µF/35V

6.3x5.8mm electrolytic capacitor with ESR 0.36Ω.

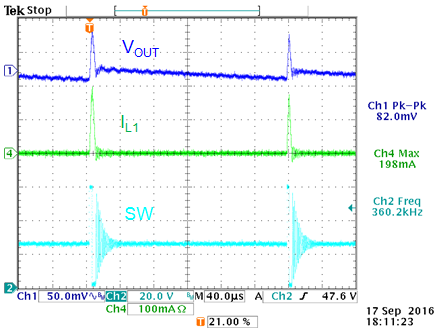

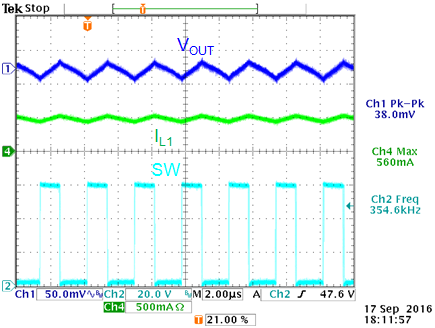

Figure 25 shows the measured output ripple in PSM

mode and CCM mode when using this electrolytic output capacitor. It is recommended

to place a small 100nF/50V ceramic capacitor in parallel with the electrolytic

output capacitor: The low ESR ceramic capacitor will filter the high frequency

spikes from the switching transitions. But this capacitor will not have

any effect on the ripple amplitude or converter stability.

|

24V output ripple in PSM mode with electrolytic

capacitor: Ripple voltage is 82mVpp

|

24V output ripple in CCM mode with electrolytic

capacitor: Ripple voltage is 38mVpp

|

|

|

|

Figure 25

Input capacitor selection: The 24V application will

have higher input ripple than the previous examples since the power level

is higher. In the 12V application we used the 100nF/100V 0603 X7R capacitor

(Murata GRM188R72A104KA35) in parallel with two pieces 2.2µF/100V

1206 X7R capacitor (Murata GRM31CR72A225KA73) giving a total combination

of 1.5µF.

If we use this same combination in the 24V application

with 60V input and 0.5A load:

will give an input ripple of around 229mVpp. For EMC reasons, it may be

necessary to add an additional 2.2µF/100V 1206 X7R and a high frequency

bead.

will give an input ripple of around 229mVpp. For EMC reasons, it may be

necessary to add an additional 2.2µF/100V 1206 X7R and a high frequency

bead.

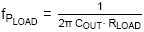

|

|

Figure 26 shows the actual input ripple

measurement with the same 1.5µF input capacitor, resulting

in a 230mVpp saw-tooth input ripple at 60V input and max 0.5A load.

The worst case RMS current in the input

capacitor in this 24V application will happen when VIN

is 48V and the load is 0.5A. The maximum RMS current will be 0.25A.

This will not be a problem for the selected input capacitors.

|

|

Figure 26

|

|

· Calculation

of compensation components.

As was shown in the 12V output application, the

electrolytic output capacitor ESR variation over temperature can have a

big impact on converter stability. If the converter has to work at very

low temperatures, a factor 3 higher ESR has to be considered. Due to this

effect, the converter bandwidth has to be set a factor 3 lower than the

standard 0.1 ‧ FSW setting. For the 24V output supply, we will

use similar bandwidth as the 12V application, around 12kHz instead of 35kHz.

For the compensation component calculations we will use the formulas as

given in chapter 2. For the output capacitance we use COUT =

47µF and output capacitor ESR = 0.36Ω.

:

With GmEA = 970µA/V, GCS = 0.9A/V and COUT

= 47µF: RCOMP becomes 124kΩ. We will choose 120kΩ.

:

With GmEA = 970µA/V, GCS = 0.9A/V and COUT

= 47µF: RCOMP becomes 124kΩ. We will choose 120kΩ.

The converter load pole

lies at 71Hz.

lies at 71Hz.

= 18.7nF. We choose 18nF.

= 18.7nF. We choose 18nF.

We use the room temperature ESR to calculate CP:

The output capacitor ESR of 0.36Ω will result in an ESR zero of at

9.4kHz. When we calculate

we can find that CP needs to be 136pF. We’ll choose a slightly

larger value of 150pF.

we can find that CP needs to be 136pF. We’ll choose a slightly

larger value of 150pF.

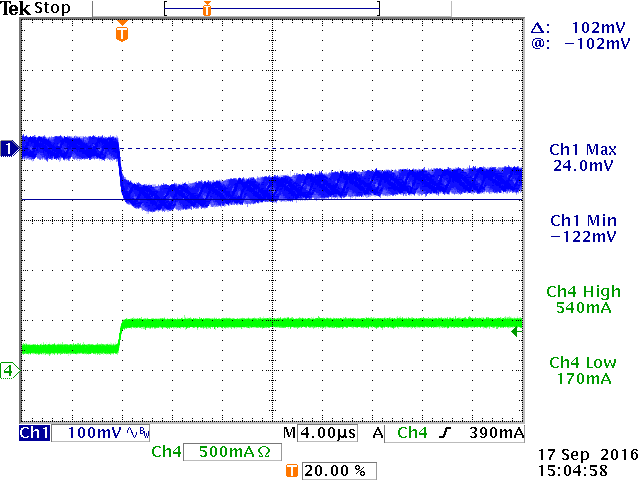

Figures 27 show the 250mA to 500mA step load response

at +25oC (longer duration), and short duration pulse load steps

at -30oC and +70oC to see the details of the transition.

|

12msec load step at +25oC

|

120µsec load step at -30oC

: OK

|

120µsec load step at +70oC

: OK

|

|

|

|

|

Figure 27

· Soft-start

design: To keep the inrush current below 100mA for the 24V application with

47µF output capacitance, the VOUT rise time must be larger

than 47µF ‧ 24V/100mA = 11msec.

,

so CSS needs to be larger than 82nF. We will choose 100nF. VOUT

rise time from 0 to 24V will be 13msec.

,

so CSS needs to be larger than 82nF. We will choose 100nF. VOUT

rise time from 0 to 24V will be 13msec.

|

|

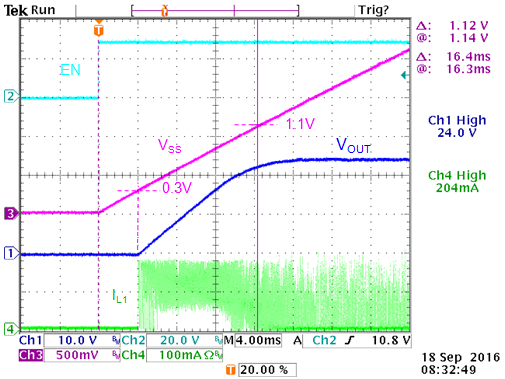

Figure 28 shows the soft-start behavior

of the 24V application.

|

|

Figure 28

|

|

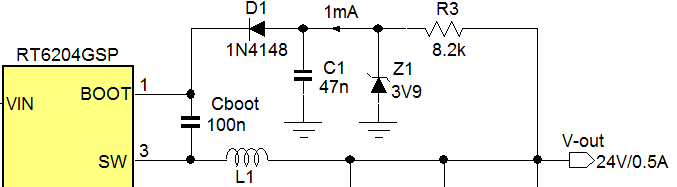

· External

Bootstrap capacitor charging circuit.

If the converter input can be lower than 37V, the

external bootstrap supply is needed. The optimal value for this bootstrap

supply is around 3.3V: Higher values like 5V can lead to too strong high-side

MOSFET drive which can lead to noise and unstable switching at certain conditions.

The 3.3V bootstrap supply can derived from the 24V output by using a zener

voltage clamp similar to the 12V application.

With an average bootstrap charge current of 1mA

and a zener bias current of 1.5mA, the zener bias resistor R3 becomes (24-3.3)/2.5mA

= 8.2k. The total power dissipation in R3 is 2.5mA2 ‧ 8.2kΩ

= 51mW, which may require a slightly larger size SMD resistor. The circuit

is shown in figure 29.

Figure 29

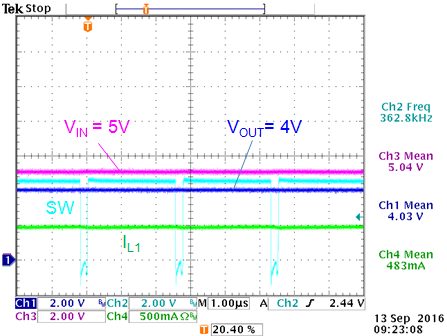

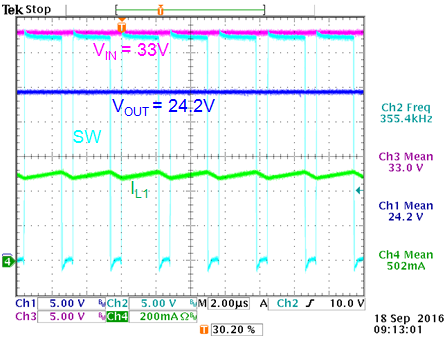

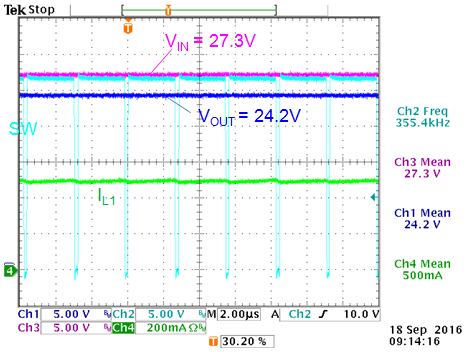

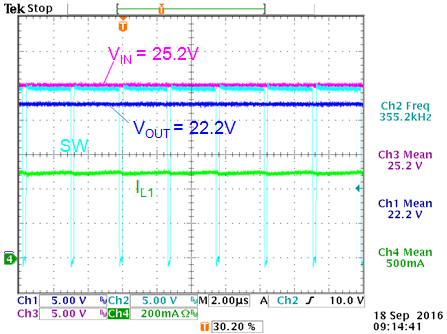

Figure 30 below shows the 24V converter operation

at maximum load when VIN is reduced: The maximum duty-cycle is

determined by the converter minimum off time which is around 200nsec, which

results in 93% max duty-cycle. The input voltage where the converter reaches

the max duty-cycle depends on load current: The I ‧ Rdson drop and inductor

I ‧ DCR drop need to be included, which is around 0.98V at 0.5A load for the

24V application. For the 24V application at 0.5A load current, the VIN

where drop-out starts to happen is then 24V/0.93 + 0.98V = 26.8V.

|

VIN = 33V: ~75% duty-cycle

VOUT = 24.2V

|

VIN = 27.3V: just at max duty-cycle:

VOUT = 24.2V

|

VIN = 25.2V: dropout mode in

max duty-cycle operation. VOUT = 22.2V

|

|

|

|

|

Figure 30

The total 24V application schematic is shown in

figure 31.

Figure 31

7. Conclusion

RT6204 buck converter can be successfully used in

applications that require wide input range and wide output range. The external

compensation and soft-start make it possible to tune the design for various

types of output capacitors. Simple formulas can be used to determining the

external key components and measured results match the calculated results

quite well.